In the early 1990s, the Parsons Vale’s Portland shops started designing a radial truck to see if they could get a bit more tractive effort on the curvier sections of the railroad. A few designs were made, prototyped, and wedged under one unfortunate class B or another, and in 1994, one of them successfully threaded the needle of curving into curves without going into an uncontrollable shimmy at speed.

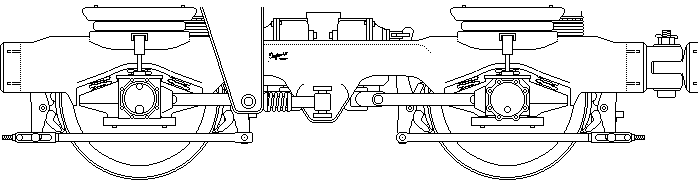

The A4R (“articulated 4-wheel radial”, originally known as the “Portland Radial Truck”) was first fitted to the class L prototype motor, then several of the class N2 motors, and then an increasing number of new units as time went on.

Initially, the fabrication of the frames for the A4R (and other) radial trucks was contracted to Dofasco, but after several years Dofasco exited the casting market (after a LARGE final order from ILW and the Portland shops) and ILW started producing welded plate frames at their Schenectady works (under the ‘ILW Trucks’ trademark.)

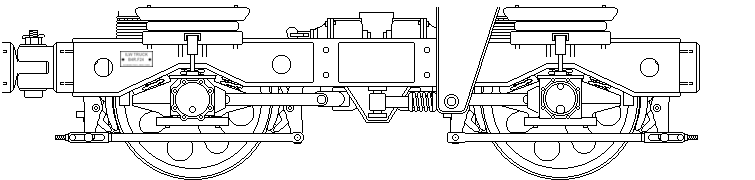

But this wasn’t the entire story; ILW had also been trying to design a radial truck, but without much success, and by 1995 gave up and commissioned (ILW is an independent subsidiary, so it gets no and gives no favors to the Parsons Vale) the Portland shops to design a version of the PRS that could be (a) fitted with 42" wheels, and (b) work on a trolley framed locomotive instead of an articulated locomotive frame.

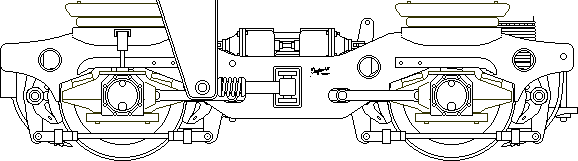

After eighteen months or so, a design was made and tested; the B4R (“bogie 4-wheel radial”) and ILW started to offer it as an option on new & remanufactured locomotives.

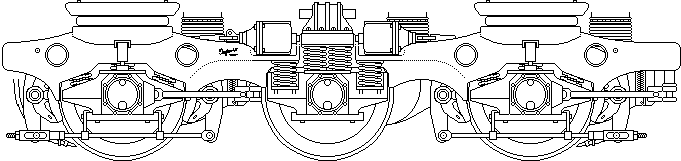

After the B4R truck had been in production for a while, Portland started working on a 3-axle variant for ILW’s big 6-axle locomotives. This one was mechanically more complicated (the center wheelset needs to slide laterally and not pivot, so there were several dead end prototypes before it, maybe(?), was worked out.

By 2007, ILW had made the Portland B4R (“bogie, 4 wheel, radial”) and B6R (“ …, 6 wheel, …”) trucks the standard for their locomotive catalogue, just in time for Dofasco to decide to get out of the castings business. Castings were then produced by Rockwell’s LFM (in Kansas, USA) but were more expensive, so Portland & ILW formed a new subsidiary to produce fabricated frames in-house instead, and in 2025 locomotives are shipped with ILW Truck F24 frames unless the purchaser specifies cast frames.